Lime mortar, and similar lime-based materials, such as lime plaster or lime wash, are vitally important in repairing old buildings. Lime mortars, renders and plasters have a different consistency to their modern cement-based counterparts; this is because lime produces soft textures and mellow colours when mixed with natural earth pigments. Most important of all, it’s porous so allows a wall to breathe and shed moisture, thus avoiding damp.

Read our expert guide to using lime mortar, lime plaster and lime wash to repair and maintain your period home. For more on transforming your home's exterior, see our complete guide.

How is lime made?

To make lime, limestone, chalks or seashells formed of calcium carbonate are burned to form quick lime. Evidence of this process dates back to prehistoric times and lime kilns were once a common sight in most villages, although they were often temporary structures. Lime began to be burned on a large scale during the Industrial Revolution and it was used not only in buildings but also in agriculture and industry.

There are two basic types of lime: nonhydraulic and hydraulic.

Non-hydraulic lime is produced from pure limestone and comes in the form of lime putty, which offers the greatest flexibility and breathability of all the limes.

Hydraulic limes are produced from limestones with naturally occurring impurities that contain a range of setting agents. Supplied in powder form, they start to set when they come into contact with water.

A third type of lime is hydrated or ‘bagged lime’ which is fundamentally a powdered form of non-hydraulic lime putty but is not generally recommended as a substitute.

See more of this Lake District dream home renovation

What are the benefits of Lime?

Environmentally-friendly: when the cement was invented in 1824, it was first used in civil engineering projects. Unlike lime, cement is inflexible and lacks porosity so can be a direct cause of damp when used in old buildings. In the early 1900s, it began to be used in the construction of homes, although it was only after World War II that its use became commonplace and, by the 1950s, traditional lime products were little used. Today, they are undergoing a revival due to the rediscovery of traditional building techniques, their ‘green’ credentials and attractive appearance.

Find out more about combatting damp and rot in old homes.

Limewash can be any colour you like, from honey to strawberry pink, by adding natural earth pigments

Walls can breathe: an understanding of lime is essential if you plan to work on a traditionally built building whether you are repointing, rendering, plastering or rebuilding walls. If you use the wrong materials, such as cement-rich mortars or renders or modern impermeable paints, you are likely to be storing up future problems. The need for old buildings to breathe, so damp and other problems are avoided, cannot be over-emphasised and by using lime you will allow this to happen.

Find out more about renders and how to render walls with our guides.

Kevin Bergin repointed the walls of his 17th century thatched cottage using lime mortar and finished them with 12 coats of limewash.

How to choose the right lime product for your home

MORE FROM PERIOD LIVING

Period Living is the UK's best-selling period homes magazine. Get inspiration, ideas and advice straight to your door every month with a subscription.

Choosing the right lime products is key but should not be daunting. Using ready mixed lime mortars and limewashes makes life easy and, generally, lime suppliers are happy to offer advice. If you want to learn more there are a variety of practical courses available. If you are employing a builder who is unfamiliar with using lime it is well worth encouraging them to have training.

As well as there being several types of lime, hydraulic lime comes in a variety of strengths with the prefix NHL (natural hydraulic lime), for example NHL 2, NHL 3.5 and NHL 5, depending on the proportion of clay and other impurities contained within the original limestone.

These impurities act as setting agents and the higher the number the less flexible and breathable the mortar will be and the better suited to harsh weather conditions. This means that a suitable mortar can be created for any situation.

Lime is highly alkaline and can burn your skin so wear goggles and gloves and, when dealing with it in a powdered form, wear a mask. Having some water to hand to wash away splashes is advisable and clean your hands afterwards.

How lime putty is made

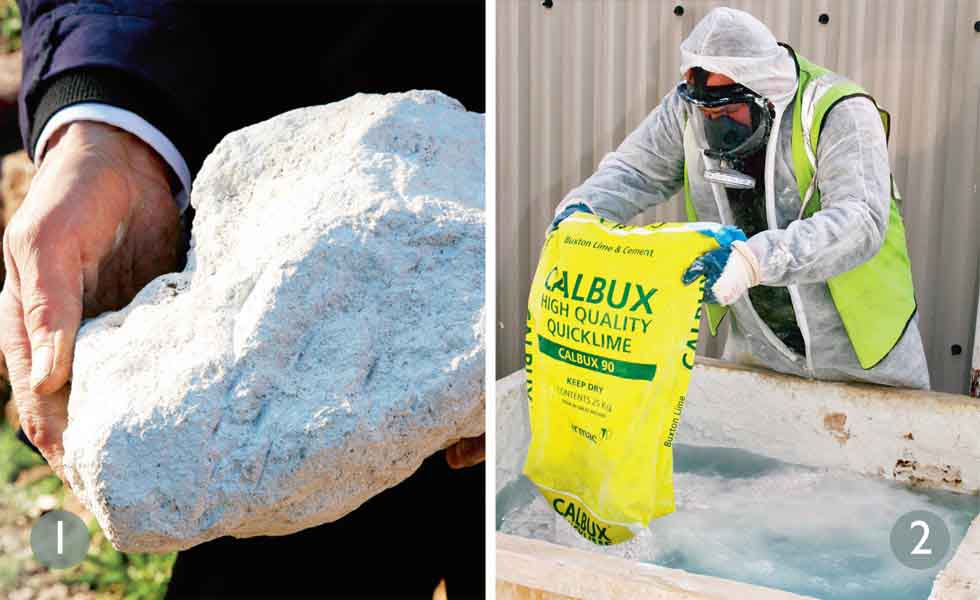

1. Limestone is burned at between 900°C to 1300°C to create quick lime, the raw material needed to create products ranging from mortar to plaster.

2. Concentrated dry quick lime is poured into a tank of water ready to be slaked or mixed to form calcium hydroxide. The process triggers strong chemical reactions, such as bubbling and hot steam, and protective gloves, goggles and breathing mask are necessary.

3. After three months, the fully matured lime putty can be dug out of the tank.

4. You can tell when lime putty is fully mature because it has the consistency of cottage cheese.

Now be inspired by these lime-washed homes:

Join our newsletter

Get small space home decor ideas, celeb inspiration, DIY tips and more, straight to your inbox!

-

How to paint on new plaster for a pro finish

How to paint on new plaster for a pro finishSee our guide to how to paint on new plaster, to achieve a professional finish, with the perfect mist coat ratio and technique.

By Hebe Hatton Last updated

-

How to restore a front door – refinish old or weather-beaten hardwood

How to restore a front door – refinish old or weather-beaten hardwoodFront door restoration is key to keep your hardwood entry door looking its finest. Clean up and refinish yours properly.

By Helaine Clare Published

-

How to render walls: a beginner's guide to rendering

How to render walls: a beginner's guide to renderingFind out how to render walls (or how much it costs to get someone else to) in our easy guide by DIY and renovation expert Michael Holmes

By Michael Holmes Last updated

-

Cladding and render: the ultimate guide to exterior finishes for your home

Cladding and render: the ultimate guide to exterior finishes for your homeTransforming your home's exterior? New cladding and render or paint in the latest finishes will modernise it and add a practical weatherproofing guard

By Lucy Searle Last updated

-

How to paint metal railings: cleaning and repairing railings and gates

How to paint metal railings: cleaning and repairing railings and gatesOld metal railings and other exterior metalwork needs regular care and attention to prevent decay, so spot the signs of wear and tear and know what action to take with this practical, step-by-step guide

By Helaine Clare Last updated

-

Expert guide to plaster in old homes

Expert guide to plaster in old homesUnderstanding and maintaining plaster in old homes is an important aspect of caring for a period property. Discover how to identify which type you have, how to go about repairing, and what it costs

By Roger Hunt Last updated

-

Plaster repair: how to fix cracks, bulges, loose plaster and damp

Plaster repair: how to fix cracks, bulges, loose plaster and dampPlaster repairs are an occasional requirement if you own an old home. These old plastered walls bring so much character to a period home, but to keep them in good condition it’s essential to be on the look out for early signs of damage

By Roger Hunt Last updated

-

How to maintain and repair an old timber frame

How to maintain and repair an old timber frameOften forming the integral framework of period properties, and an aesthetic feature, timber posts and beams must be treated with care and attention to ensure their longevity

By Roger Hunt Published